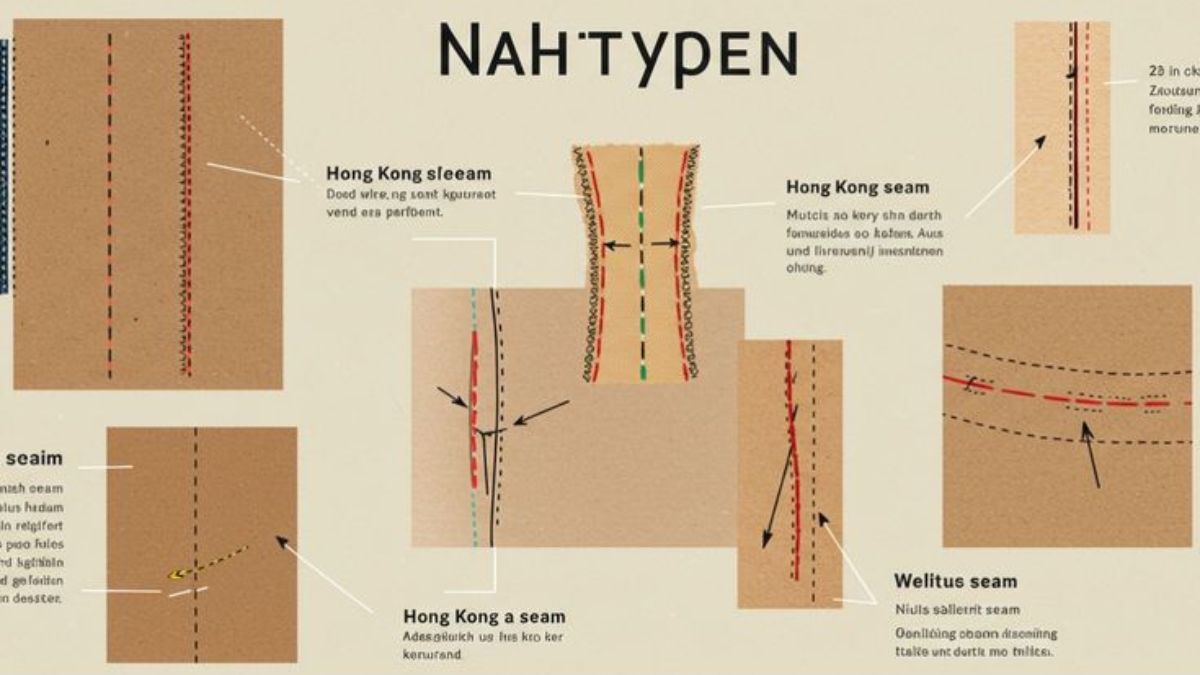

When it comes to sewing—whether you’re crafting a handmade garment at home or working in a high-volume textile factory—the foundation of every well-made piece lies in its seams. These connections between fabric layers determine not only the durability and structure of the final product but also its appearance and comfort. In German-speaking sewing and textile contexts, these seam types are collectively referred to as nahttypen. While the English term “seam types” is widely used globally, understanding nahttypen offers insight into standardized classifications that guide professionals and hobbyists alike in choosing the right construction method for each project.

This article provides a detailed exploration of nahttypen, covering their definitions, categories, practical applications, strengths, and considerations for selection. Whether you’re a beginner learning to sew your first dress or a seasoned tailor refining your technique, grasping the nuances of nahttypen will significantly enhance your craftsmanship and efficiency.

Table of Contents

What Are Nahttypen?

The term nahttypen (singular: Nahttyp) translates directly to “seam types” in English. In the textile and garment industry, nahttypen refer to standardized methods of joining two or more pieces of fabric together using stitches. These methods are not arbitrary; they follow internationally recognized classifications, most notably those established by organizations like the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN). The ISO 4915 standard, for instance, categorizes seams into eight main classes (Class 1 through Class 8), each with distinct structural and functional characteristics.

Understanding nahttypen is essential because the choice of seam affects:

- Durability: How well the seam holds up under stress or repeated washing.

- Appearance: Whether the seam is visible, decorative, or hidden.

- Flexibility: How the seam behaves when the garment moves or stretches.

- Fabric compatibility: Certain seams work better with specific fabric weights or types (e.g., knits vs. wovens).

- Production efficiency: Some nahttypen are faster to sew, making them ideal for mass production.

By mastering nahttypen, sewers can match the right seam to the right project—ensuring both functionality and aesthetic appeal.

The Eight Main Classes of Nahttypen (ISO 4915)

The ISO 4915 standard is the most widely accepted framework for classifying nahttypen. Below is a detailed overview of each of the eight classes, including their structure, common uses, and advantages.

Class 1: Superimposed Seams

Superimposed seams are the most common type of seam used in both home sewing and industrial production. In this nahttyp, one fabric edge is placed directly on top of another, and they are stitched together along the seam line. The raw edges may be finished separately (e.g., with a serger or zigzag stitch) to prevent fraying.

Examples:

- Plain seam

- French seam (a variation that encloses raw edges)

- Flat-felled seam

Applications:

Used in shirts, dresses, trousers, and most woven garments. Ideal for medium to heavy-weight fabrics.

Advantages:

- Simple and quick to construct

- Strong and versatile

- Easy to press open or to one side

Class 2: Lapped Seams

In lapped seams, one fabric piece overlaps the other, and stitching secures the overlap. Unlike superimposed seams, there is no alignment of raw edges; instead, one layer covers the edge of the other.

Examples:

- Patch pockets

- Denim jeans (e.g., yoke seams)

- Raincoats and outerwear

Applications:

Common in workwear, outerwear, and garments requiring water resistance or added strength.

Advantages:

- Provides extra thickness and durability

- Prevents water penetration (when stitched correctly)

- Creates a clean, layered look

Class 3: Bound Seams

Bound seams use a separate strip of fabric (bias tape or binding) to enclose the raw edges of one or more fabric layers. This nahttyp is both functional and decorative.

Examples:

- Bound seam on unlined jackets

- Armhole or neckline finishes in lingerie

Applications:

Frequently used in lightweight or delicate fabrics where raw edges need protection without bulk.

Advantages:

- Neat, professional finish

- Prevents fraying

- Adds a decorative touch

Class 4: Flat Seams

Flat seams join two fabric edges so they meet but do not overlap, resulting in a smooth, flat surface on both sides. This is achieved using specialized machines (e.g., coverstitch or flatlock machines) that interlock threads over the abutted edges.

Examples:

- Athletic wear

- Underwear

- T-shirts and knitwear

Applications:

Ideal for stretch fabrics and garments requiring comfort against the skin.

Advantages:

- No bulk or ridge on the inside

- Excellent stretch and recovery

- Comfortable for close-fitting garments

Class 5: Decorative Seams

As the name suggests, decorative seams prioritize visual appeal over structural function. They often incorporate ornamental stitching, contrasting threads, or special techniques.

Examples:

- Topstitching

- Piped seams

- Quilting lines

Applications:

Used in fashion design, home décor, and high-end tailoring to add visual interest.

Advantages:

- Enhances design aesthetics

- Can reinforce seams while looking stylish

- Customizable with thread color and stitch pattern

Class 6: Edge-Finished Seams

These nahttypen focus on finishing a single fabric edge rather than joining two pieces. They prevent fraying and provide a clean border.

Examples:

- Hemmed edges

- Rolled hems

- Overlock-finished edges

Applications:

Used on garment hems, scarf edges, and any exposed fabric border.

Advantages:

- Prevents unraveling

- Gives a polished look

- Can be minimal (e.g., narrow hems) or substantial (e.g., double-fold hems)

Class 7: Applied Seams

Applied seams involve attaching a separate piece of material—such as lace, trim, or elastic—directly onto the fabric surface. While not always a “seam” in the traditional sense, this nahttyp is included due to its functional role in garment construction.

Examples:

- Elastic waistbands

- Lace appliqués

- Binding on necklines

Applications:

Common in lingerie, swimwear, and children’s clothing.

Advantages:

- Adds functionality (e.g., stretch, closure)

- Enables creative design elements

- Can replace traditional seams in certain contexts

Class 8: Other Seams

This category includes nahttypen that don’t fit neatly into the previous seven classes. It’s a catch-all for innovative or hybrid seam constructions.

Examples:

- Welt seams

- Mock flat-felled seams

- Heat-sealed seams (in technical textiles)

Applications:

Used in specialized garments like military uniforms, sportswear, or technical outdoor gear.

Advantages:

- Offers solutions for unique design or performance needs

- Encourages innovation in textile engineering

Choosing the Right Nahttyp: Key Considerations

Selecting the appropriate nahttyp is not just about following a pattern—it’s a strategic decision influenced by several factors:

1. Fabric Type and Weight

- Lightweight fabrics (chiffon, silk): Require delicate nahttypen like French seams or bound seams to avoid bulk and prevent fraying.

- Medium-weight fabrics (cotton, linen): Work well with plain seams or flat-felled seams.

- Heavy fabrics (denim, canvas): Benefit from lapped or double-stitched seams for added strength.

- Knits: Need stretch-compatible nahttypen like flat seams or serged seams to maintain elasticity.

2. Garment Function

- Everyday wear: Prioritize durability and comfort—superimposed or flat seams are ideal.

- Outerwear: Use lapped or bound seams for weather resistance.

- Activewear: Flatlock or coverstitch seams ensure flexibility and comfort.

- Formal wear: French seams or hand-finished seams provide a refined interior.

3. Production Method

- Home sewing: Simpler nahttypen like plain seams are practical without industrial machines.

- Industrial manufacturing: High-speed machines enable complex nahttypen like flatlock or bound seams at scale.

4. Aesthetic Goals

If the seam will be visible (e.g., in a design detail), consider decorative nahttypen with contrasting thread or topstitching. Hidden seams should be neat and secure without drawing attention.

5. Care and Maintenance

Some nahttypen withstand frequent washing better than others. For example, serged seams may unravel over time if not secured properly, while flat-felled seams remain intact through many laundry cycles.

Common Mistakes When Working with Nahttypen

Even experienced sewers can make errors when selecting or executing nahttypen. Here are some frequent pitfalls to avoid:

- Using the wrong seam for stretch fabric: A straight-stitch plain seam on jersey will snap when stretched. Always use a stretch-compatible nahttyp.

- Ignoring seam allowances: Too narrow, and the seam may pop; too wide, and it adds unnecessary bulk.

- Skipping edge finishing: On fabrics prone to fraying, leaving raw edges untreated can ruin a garment over time.

- Mismatching thread and fabric: Heavy thread on delicate fabric can cause puckering or tearing.

- Overlooking pressing: Proper pressing sets the stitches and ensures a professional finish—don’t skip this step!

The Role of Nahttypen in Sustainable Fashion

As the fashion industry shifts toward sustainability, nahttypen play a surprisingly important role. Durable seams extend a garment’s lifespan, reducing the need for replacements and minimizing textile waste. Additionally, certain nahttypen facilitate disassembly—critical for recycling or upcycling. For example, garments constructed with easily removable seams (like simple superimposed seams) can be taken apart more efficiently than those with fused or glued layers.

Designers focused on circular fashion often choose nahttypen that balance strength with reversibility, proving that even technical choices like seam selection can support environmental goals.

Conclusion

Mastering nahttypen is more than a technical skill—it’s a gateway to better design, longer-lasting garments, and more efficient production. From the humble plain seam to the intricate flatlock construction, each nahttyp serves a purpose shaped by fabric, function, and form. By understanding the eight ISO classes and considering factors like material, use case, and aesthetics, sewers at every level can make informed decisions that elevate their work.

Whether you’re repairing a favorite shirt, designing a new collection, or exploring sustainable practices, your choice of nahttypen matters. These seemingly small details are the invisible architecture of every textile product we wear and use. So the next time you thread your needle or load fabric into a sewing machine, remember: the right nahttyp isn’t just about joining fabric—it’s about creating something that lasts, fits, and inspires.

In a world where fast fashion often overlooks craftsmanship, returning to the fundamentals of nahttypen reminds us that quality begins with how things are put together—stitch by careful stitch. And as you continue your sewing journey, keep the concept of nahttypen at the heart of your process, for it is through these seams that both function and beauty are truly sewn.